Maintaining your Bissell ProHeat 2X is crucial for its longevity. This guide assists with repairs‚ emphasizing genuine parts. Proper maintenance ensures peak performance and tackles tough stains effectively.

Importance of Genuine Bissell Parts

Using genuine Bissell parts is essential for maintaining the performance and longevity of your ProHeat 2X carpet cleaner. Authentic components are designed specifically for your machine‚ ensuring a proper fit and optimal functionality. Counterfeit or generic parts may not meet the same quality standards‚ potentially leading to reduced cleaning effectiveness‚ damage to other components‚ or even complete machine failure. Opting for genuine Bissell parts guarantees that your carpet cleaner operates as intended‚ providing reliable cleaning power and extending its lifespan. They ensure that the machine continues to work efficiently.

Understanding Bissell ProHeat 2X Models

The Bissell ProHeat 2X series includes various models like the 8920‚ 1391‚ and Revolution. Each has unique features‚ but all share the core ProHeat 2X technology for deep cleaning.

Common ProHeat 2X Series

The Bissell ProHeat 2X series is diverse‚ featuring models like the 8920‚ often referenced in service manuals‚ and the 1391 and 1383 series. The Revolution models‚ such as the 1548‚ 1550‚ and 1551‚ are also popular for their pet-focused cleaning capabilities. These variants share core components but may have slight differences in design and features. Understanding your specific model is key for accurate part identification and repair. Manuals and diagrams often group these models‚ indicating common repair procedures.

Locating Bissell ProHeat 2X Parts

Finding correct parts involves using online catalogs and diagrams. These resources aid in identifying specific components for your ProHeat 2X model‚ ensuring accurate replacements.

Online Parts Catalogs and Diagrams

Numerous online resources provide detailed parts catalogs and diagrams for Bissell ProHeat 2X models. These platforms often feature exploded views‚ making it easier to identify and order specific components. Look for sites that offer genuine Bissell parts‚ ensuring compatibility and optimal performance. These diagrams are invaluable for DIY repairs‚ allowing users to pinpoint the exact part needed‚ from spray nozzles to pump components. Utilizing these resources greatly simplifies the repair process‚ offering a visual guide for disassembly and reassembly;

Key Components and Their Functions

The Bissell ProHeat 2X includes vital parts like the spray nozzle‚ pump‚ and manifold. Each component performs a specific role in cleaning‚ ensuring effective operation.

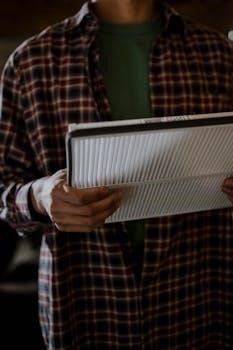

Spray Nozzle Assembly

The spray nozzle assembly is a critical part of your Bissell ProHeat 2X‚ responsible for delivering the cleaning solution onto your carpets. It ensures even distribution of the formula‚ essential for thorough cleaning. The nozzle can sometimes become clogged‚ leading to poor performance or no spray at all. Regular cleaning of this part is necessary to maintain optimal function. The nozzle components can include several small pieces‚ and a special tool might be needed for proper cleaning.

Pump and Solenoid Valve

The pump and solenoid valve work together in the Bissell ProHeat 2X to control the flow of cleaning solution. The pump is responsible for creating the necessary pressure to push the solution through the system‚ while the solenoid valve regulates the on/off flow. If these components fail‚ you may experience low or no spray. The Bissell pump (P439) is a part of this system. It is essential to check for any obstructions that might impede their performance.

Manifold and Automix System

The manifold and Automix system in the Bissell ProHeat 2X are responsible for the proper mixing of water and cleaning solution. The manifold distributes the mixed solution to the spray nozzle assembly‚ ensuring even application. The Automix feature simplifies this process by automatically blending the correct ratio. A faulty manifold or Automix system can lead to uneven cleaning or improper solution dispensing. It is crucial to ensure all components are clean and functioning correctly to maintain optimal cleaning performance. The manifold assembly (2036767) is an important component to consider.

Troubleshooting Common Issues

Addressing common issues like low or no spray is essential for effective cleaning. Understanding the causes and solutions will help maintain your ProHeat 2X’s performance.

Low or No Spray Problems

Experiencing low or no spray from your Bissell ProHeat 2X can be frustrating. Often‚ this issue stems from a clogged nozzle‚ which can be resolved with a simple cleaning procedure using the provided tool. Ensure the formula tank is properly inserted and the SmartClean dial is set correctly. The pump or solenoid valve might also be a culprit if the issue persists‚ requiring inspection and possible replacement. Check for blockages in the manifold system. Always refer to the user manual for specific troubleshooting steps.

Maintenance and Cleaning

Regular maintenance ensures your Bissell ProHeat 2X operates efficiently. Cleaning the nozzle and other components prevents clogs and maintains optimal performance. Follow manual guidelines for detailed procedures.

Nozzle Cleaning Procedures

Proper nozzle cleaning is essential for maintaining your Bissell ProHeat 2X’s spray performance. Begin by removing the nozzle assembly‚ often secured with screws. Use a specialized nozzle cleaning tool‚ if available‚ or a small brush to clear any blockages. Rinse the nozzle thoroughly under warm water to remove any remaining debris. Ensure all parts are fully dried before reassembling; Regular cleaning prevents clogs and ensures even distribution of cleaning solution. This will allow your machine to effectively clean and remove stains.

Using the User Manual

User manuals are vital for understanding your Bissell ProHeat 2X. They offer guidance on operation‚ maintenance‚ and troubleshooting. Accessing these resources online is straightforward.

Accessing User Manuals Online

Finding your Bissell ProHeat 2X user manual online is simple. Visit the official Bissell website and navigate to the “Support” or “Manuals” section. You can typically search by your model number‚ such as the 8920 series or 1391 series‚ to find the correct guide. These digital manuals provide detailed instructions on usage‚ maintenance‚ and troubleshooting steps. Downloadable PDFs are usually available‚ allowing you to save and reference the manual offline. User manuals are crucial for understanding your specific model and ensuring proper care of the machine. They often contain diagrams and detailed parts lists as well.

Finding Service Center Information

Locate authorized Bissell service centers through their official website. These centers offer expert repair and maintenance services for your ProHeat 2X‚ ensuring proper care.

Authorized Service Centers for Bissell

Bissell provides a network of authorized service centers that are equipped to handle repairs and maintenance for your ProHeat 2X series. These centers employ trained technicians who have expertise in diagnosing and fixing issues with Bissell products. Using an authorized service center ensures that genuine Bissell parts are used‚ maintaining the integrity and performance of your carpet cleaner. You can find locations of these centers through the Bissell website or by contacting customer service. This helps to ensure reliable and effective service for your machine.

Disassembly of Proheat 2x Revolution Pet Pro

Disassembling your Proheat 2x Revolution Pet Pro requires a Phillips and a flat head screwdriver. Ensure the machine is off and unplugged before beginning the process.

Step-by-Step Disassembly Guide

Begin by ensuring the Bissell ProHeat 2X Revolution Pet Pro is unplugged and empty. Remove the clean water tank by lifting it straight up. Unscrew the cap from the water tank. Using a Phillips head screwdriver‚ detach all visible screws on the exterior casing. Carefully separate the housing components. Pay attention to the internal wiring. Take photos at each stage of disassembly to aid in reassembly. Use a flathead screwdriver to gently pry apart any stubborn parts. Note the placement of any small parts‚ like screws or washers. Remember to document the steps‚ it will help when putting it back together.